| 2021/02/21 |  |

|---|---|

| 2021/07/16 |

〈NEW〉Our Company Video is uploaded.

|

| 2021/07/04 |

New websites in German and Spanish.Providence Technology has new websites in German and Spanish,

welcome everyone who is interested in our products to visit our new web. |

| 2019/12/04 |  |

| 2019/9/16 |  |

| 2017/8/30 | The Market Share of PROVIDENCE’s New Machining Centers Has Reached a New Peak |

| 2016/7/26 | PROVIDENCE's New Machining Centers Make More and Higher Sales

|

| 2015/10/1 | Emo Milano is a 6 day event being held from 5th October to the 10th October 2015 at the Fiera Milano in Milano, Italy. Hall 5,Stand No.B14 Exhibition(PDF) |

Trust, Truth, Honesty,

Love, Help, Sharing

Providence Technology Co., LTD was founded in 2006. “ High quality, High stability, High accuracy," is our purpose. To maintain the best quality is on our main thinking for sustainable management.

Providence Technology took a serious attitude about quality control. The serious thinking "better than better” is the basic requirement for our products and employees. We are lucky to get continuous orders from all over the world due to the trust of customers and their confidence in our products.

All casting and materials parts, Providence Technology offer 100% guarantee machining and assembling in Taiwan. For the future, we insist to walk on the road of “high quality, high stability, high accuracy”, and hope you will grow up together with Providence Technology.

Providence GiGa series help customers to increase efficiency and are ideal for mold machining and precision parts machining. No matter which you select, it will provide all the precision, performance and minimum trouble you require.

The Characteristic of Providence GiGa Series

3 AXES LINEAR WAYS

- MVL and APC series are representative.

- 3axes adopt high precision liner ways. The travels are light and smooth, suitable for the needs of high-speed precision machining.

- It is designed for high-speed, high-precision mold making, can be optional with high-speed direct spindle or built-in spindle.

3 AXES BOX WAYS

- MCV series is representative.

- The spans of 3axes are wider than normal design in order to increase stability for heavy machining.

- The extra wide box ways are hardened, precision ground and coated with wear-resistant material. The surfaces of box ways are also scraped for precise and smooth movements.

2 AXES LINEAR WAYS AND 1 AXIS BOX WAY

- MLC series is representative.

- X axis and Y axis adopt high precision liner ways. The travels are light and smooth, suitable for the needs of high-speed precision machining.

- The other box way of Z axis is hardened, precision ground and coated with wear-resistant material. The surfaces of box ways are also scraped for precise and smooth movements.

APC SERIES

- It drives by servo motor within 7 sec.

- An air blast device is applied for cleaning the positioning blocks before pallet positioning; hence high positioning accuracy is ensured.

- The positioning accuracy:±0.005mm; The repeatability accuracy: ±0.005mm.

- 3axes adopt high precision liner ways. The travels are light and smooth, suitable for the needs of high-speed precision machining. It allows the operator to set up workpieces while the machine is performing cutting, to increase efficiency.

- Built-in hydraulic power unit and oil cooler

5 AXIS SERIES

- The 5-axis simultaneously technology to enhance complex machining accuracy and quality.

- Table surface and c-axis center at the same level, to improve the accuracy of machining datum point (program reference point).

HORIZONTAL SERIES

- It is designed moving column and fast feeding.

- It is with reliable axial positioning, can shorten machining time.

- It is with high rigidity ball screw and linear guideway, can reach high speed, high precision and high efficiency. It is also with auto pallet changer to save space and machining time.

- The tables are with servo auto changer system, can support five axis machining and with hydraulic locking system allow space saving and improve performance. Customers will save costs and improve productivity more than 200%.

-

DEFORMATION-FREE STRUCTURE

All structural parts of the machine are manufactured from high quality Meehanite cast iron, tempered and stress relieved for deformation-free performance. The structural parts are scientifically rib reinforced to increase the machine rigidity and stability and sassure lifetime accuracy of the machine.

SYMMETRICALLY CONSTRUCTED SPINDLE HEAD

The spindle head is a symmetrical construction to eliminate offset problems during machining. In addition, the symmetrical construction also prevents unsteadiness problems of the spindle head caused by heat transfer from the spindle motor.

INTEGRATED BALL SCREW SUPPORT AND STRUCTURAL PART

The ball screw support and structural part are one-piece construction, which provides added rigidity and stability during machining.

COOLANT JETS AROUND SPINDLE

The coolant jets around the spindle are designed to eliminate interference in the machining area resulting from conventional coolant nozzles. Another benefit is that they increase the cooling effect on the work piece.

FEM ANALYSIS

The structural parts are analyzed by using the Finite Element Analysis (FEM). This analysis will ensure the best rigidity of the machine, excellent resistance for high speed machining and low gravity center of the machine structure.PRECISION BALL SCREWS

Pretension class C3 ball screws are employed to eliminate backlash problems, while assuring superior feed accuracy and stability. All ball screws are carefully inspected during installation.Y-SHAPED COLUMN

The column is designed with a Y-shape construction to ensure outstanding rigidity and stability.

NEAT ELEGANT MACHINE BACK

To ensure a neat and eleant outlook of the machine back, all pipings are completely concealed in the enclosure. This not only avoids damage on pipings, but also permits convenient maintenance of the machine.

NEAT OUTLINE AND ULTIMATE SAFETY

QUALITY

In order to guarantee the highest possible accuracy, careful scraping is followed by attentive inspections to eliminate alignment deviation.

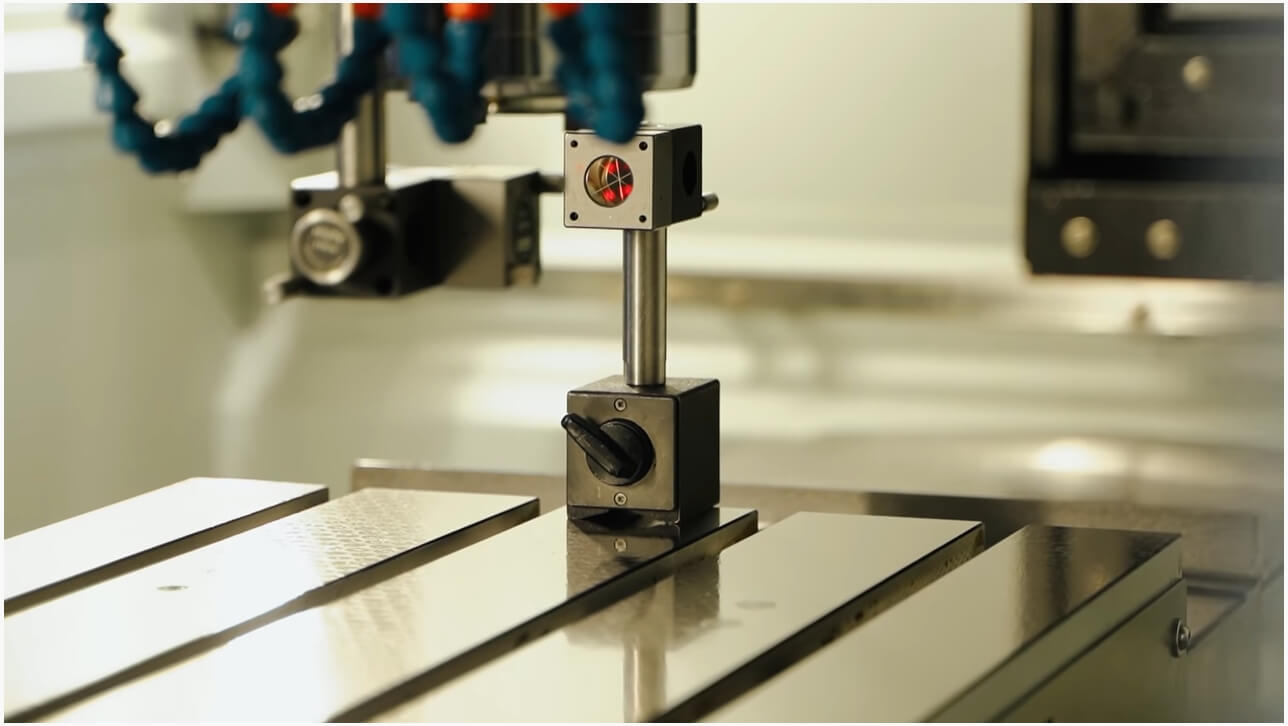

LASER INSPECTION ON THREE AXES

Each machine is subject to laser inspection on three axes. By using the laser unit, positioning accuracy and repeatability can be inspected. The laser inspection in conducted according to German VDI3441 standards.

BALL BAR TEST FOR CIRCULARITY

After assembly, each machine is inspected by a sophisticated ball bar tester to check the machine’s servo accuracy, static and dynamic geometric accuracy.

| Model / Feature | MVL | APC | MCV | MLC | HMC | 5-Axis |

|---|---|---|---|---|---|---|

| Deformation-free structure | ● | ● | ● | ● | ● | ● |

| Symmetrically constructed spindle head | ● | ● | ● | ● | ● | |

| One-piece constructed motor base and bearing housing | ● | ● | ● | ● | ● | ● |

| Coolant jets around spindle | ● | ● | ● | ● | ● | ● |

| High speed and heavy cutting operations | ● | ● | ● | ● | ● | ● |

| Outstanding rigidity and stability | ● | ● | ● | ● | ● | ● |

| Automatic pallet changer (APC) | ● | |||||

| Multi-Axis Free-Form Surface Machining | ● | ● | ||||

| Counter balance weight properly guided for increased stability | ● | ● | ● | |||

| Neat elegant machine back | ● | ● | ● | ● | ● | ● |

| Neat outline and ultimate safety | ● | ● | ● | ● | ● | ● |

| Laser inspection on three axes | ● | ● | ● | ● | ● | ● |

| Ball bar test for circularity | ● | ● | ● | ● | ● | ● |

| Quality | ● | ● | ● | ● | ● | ● |

You can download detail E-Catalog at web side if you need.

- BUILT-IN HYDRAULIC POWER UNIT AND OIL COOLER

The hydraulic power unit and oil cooler are installed in the machine to save installation space and time. - AUTOMATIC PALLET CHANGER (APC)

Upon request, a pallet change drive by servo motor is available.

A air blast device is applied for cleaning the positioning cones before pallet positioning; hence hih positioning accuracy is ensured. - COUNTER BALANCE WEIGHT PROPERLY GUIDED FOR INCREASED STABILITY

The counter balance system on the Z-axis has a guide that allows the spindle head to move stably, resulting in higher machining accuracy. - UNIFORM LUBRICATION ASSURED

A volumetric oil distributer is equipped in the lubrication system to ensure uniform oil supply to each lubrication point.

The use of the oil distributer also helps improve motion smoothness of all axes. - RUGGEDLY CONSTRUCTED SADDLE AND TABLE

The box shaped saddle and table are specially designed to provide heavy load resistance capability, resulting in better machining accuracy.

The MVL-750U from Providence is designed to meet high accuracy, high speed and high efficiency machining requirements. This machine allows the operator to set up work pieces while the machine is performing cutting, providing a reduction for non-cutting time and an increase in efficiency.

【 5 AXIS MACHINING CENTER-MVL & MAX SERIES】

For the needs of aerospace industry, GiGa Series actively involved in R & D of vertical 5-axis machining center, the current model is:MVL-25X , MVL-40X , MAX-620U ... other models, to satisfy industrial and manufacturing production needs.

- The 5-axis simultaneously technology to enhance complex machining accuracy and quality

- Table surface and c-axis center at the same level, to improve the accuracy of machining datum point (program reference point)

- It is suitable for use in aerospace industry, electronics industry, automotive industry, medical industry and mold industry which need to do machining complicated and sophisticated working-pieces. This MAX series can help user to reduce preprocessed time for fixing working-pieces.

【ABOUT HMC HORIZONTAL MACHINING CENER】

The GiGa Series small Horizontal Machining Center is moving column design, fast moving, under at high feeding can has less inertia, high precision and high reliability; reliable axial positioning, can shorten machining time, with high rigidity ball screw and linear guideway design, to reach high speed, high precision and high efficiency, also with auto. pallet changer design to save space and machining time.

RAPID TABLE EXCHANGE:

Table by servo auto. changer system can support five axis machining and with hydraulic locking system allow space saving and improve performance, customers will benefit save investment and improve productivity by 200 %.

THE MOVING COLUMN AND FAST FEEDING DESIGN:

Moving column design with direct motor drive system, under moving at high feed can has less inertia, high precision and high reliability; reliable axial positioning, can shorten machining time.

About Video

Download E-Catalog

| 2021/02/21 |  |

|---|---|

| 2021/07/16 |

〈NEW〉Our Company Video is uploaded. |

| 2021/07/04 |

New websites in German and Spanish.Providence Technology has new websites in German and Spanish,

welcome everyone who is interested in our products to visit our new web. |

| 2019/12/04 |  |

| 2017/9/16 |  |

| 2017/8/30 | The Market Share of PROVIDENCE’s New Machining Centers Has Reached a New PeakAutomatic Machining Manufacturing System For 24-hour Production Satisfies with Aerospace Industry

Providence Technology Co., Ltd who emerges in the global machining center market, has two brands “PROVIDENCE” and “GiGa” and continues doing R&D in manufacturing machining center area, and has complete model under serious attitude about quality control and quantity control to reach a new peak sales. In recent years, Providence has cooperated with Parkson who is known CNC tilting rotary table manufacturer in Taiwan to develop two series-Horizontal machining center and Vertical 5-axis machining center. In the last year, Providence cooperated with Euro robot manufacturer to develop automatic machining manufacturing system in industry 4.0. Customer has done 24-hour production. Providence will have a next new peak in market share in the future. Providence’s management philosophy is “high quality, high stability and high accuracy”. They insist on the conviction of “quality first” and “sustainable operation”, and keep going to develop high-performance Vertical 5-axis machining center with mass production including A/C axis type MVL-25X nd MVL-40X and B/C axis MAX-620U for demand in the market. This time Providence cooperates with Pakson and Euro robot manufacturer to develop automatic machining manufacturing system in industry 4.0 which is adopted MVL-40X model (The travel of X, Y and Z axis is 700 x 600 x 500mm. The spindle is BT40. )It installed CNC tilting rotary table with C axis table size Ø400mm, and A axis tilting angle is from +30 to -120 degree. Five-axis simultaneous motion technology makes complicated machining quality and accuracy better. The table of CNC tilting rotary table and C axis center height are at the same height. This design could increase the position accuracy of machining point. All casting and materials parts, Providence Technology offers 100% guarantee machining and assembling in Taiwan including automatic machining manufacturing system in industry 4.0. This system combines Euro robot technology to reach the stage for 24-hour production and Parkson rotary table mechatronics technology not only to increase the machining speed, machining accuracy and machining travel which is better than same type in the market, but also to have excellent machining capability and improve production. (Above Is Excerpt From Taiwan Economic Daily News And Translated Into English.) |

| 2016/7/26 | PROVIDENCE's New Machining Centers Make More and Higher SalesProvidence Technology Co., LTD has taken a serious attitude about quality control and quantity control for the past 10 years. They also established two brands "PROVIDENCE" and "GiGa" for selling machining centers to all over the world. Providence has always treated the production with a serious attitude. With the product collection becomes completed, the sales have also reached the highest point ever. Providence has also released two types of products - "Horizontal Machining Center" and "5 Axis Machining Center" this year, and hoping these two products will help to increasing the market share in the future too. Referring to the management team of Providence Technology, they have always believe in: "Trust, Truth, Honesty,

Love, Help, Sharing" Providence Technology keeps focusing on product innovation to satisfy and surpass various demands from different customers and industries. The product series are including "VERTICAL Machining Center" (MVL series, MLC series, MCV series and APC series) and "HORIZONTAL Machining Center" (Moving Column type: HMC-320, is suitable for mass production and FMS system in order to increase machining efficiency). About the series "5 Axis Machining Center", there are new products- BC FIVE AXIS With Moving Column Type: MAX-630U; also the standard type: MAX-25X and MAX-40X (AC FIVE AXIS). Above 5 axis machining centers can satisfy with the demands from different machining industries. All of their product collections are made with high accuracy and provide high efficiency. The motto “better than better” is the basic requirement for Providence Technology’s products and employees. They think they are lucky to have support from not only domestic customers, but also foreign customers. Their market is worldwide, includes Europe, America, Japan, China and the countries of Southeast Asia. Their sales growth rate keeps an average of 10 percentages for the past years. For the future, Providence Technology insists to maintain "high quality, high stability and high accuracy", and to keep their technology and skill up to date. (Above Is Excerpt From Taiwan Economic Daily News And Translated Into English.) |

| 2015/10/1 | Emo Milano is a 6 day event being held from 5th October to the 10th October 2015 at the Fiera Milano in Milano, Italy. Hall 5,Stand No.B14 Exhibition(PDF) |

Providence Technology Co., LTD.

- No.1016-1, Qingguang Rd.,Wuri Dist.,

Taichung City 414, Taiwan(R.O.C) - +886-4 233 59089

- +886-4 233 59079

- sales1@providence.com.tw